|

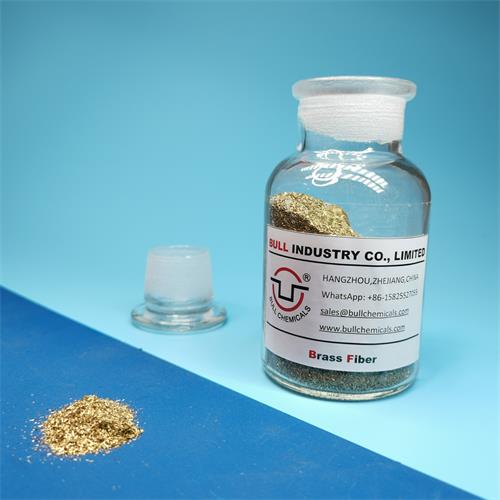

Brass Fiber|Brass Chips|Brass ScrapsHits:3332

Time:2015-04-16 09:48:58 |

|---|

PRODUCTION DESCRIPTION:

Brass is a very common metal friction material filler, its good heat transfer coefficient contributes to transfer the heat generated from frictional touch face to in-part of the friction products, thus to control of the temperature of the brake components. The chemical composition and micro-structure of the fiber make Brass an ideal material for use in friction materials of high performance and high duty levels. Brass also has a relatively low Mohs scale of hardness, which contributes to anti-friction in high temperature. In Europe, brass will be widely used in brake pads, especially in high-class brake pads friction materials, 5%-8% will be much more proper.

GRANULARITY(SIEVE ANALYSIS,PARTICLE SIZE)

Length of Fiber (lf): 1.0 - 5.0mm

Diameter of Fiber (df): 0.15 - 0.25mm

Length to Diameter Ratio (lf/df): 6 - 20

|

Sieve(mm) |

Specified (%) |

Typical(%) |

|

>0.25 |

0.0-2.0 |

0.2-1.8 |

|

0.25 |

10.0-40.0 |

20.0-36.0 |

|

0.15 |

50.0-80.0 |

58.0-72.0 |

|

<0.15 |

0-12.0 |

2.0-10.0 |

APPEARANCE

Shape:Needle like, Fiber

Color:Pale yellow

PHYSICAL PROPERTIES

Specific Gravity(g/cc): 8.50

Apparent Density(g/cc): 1.2-3.5

CHEMICAL COMPOSITION

|

Elements |

Cu |

Zn |

Pb |

Sn |

Fe |

Ni |

Al |

|

Rate(%/w.t.) |

59 |

Remain |

1.0-3.0 |

0.0-0.5 |

0.0-0.5 |

0.0-0.5 |

0.0-0.5 |

PACKAGE

1. 25KG/bag, double sheet paper bags with plastic bag.

2. Opened bags must be carefully resealed and kept upright to prevent leakage. Stored in original packages in a dry, cool and well ventilated areas to prevent from direct sunlight.

3. Use appropriate to avoid environment contamination.