Effect of calcium sulfate whiskers on friction material of brake pads

A Calcium sulfate whiskers are safe materials.

B Calcium sulfate whiskers can be regarded as an anchor point to promote the formation of the third body layer, creating a very suitable condition for stabilizing the friction coefficient, so its shape is excellent.

C. Calcium sulfate whiskers are excellent in heat resistance, because at up to 1000 degrees Celsius, it does not show thermal degradation, provides appropriate mechanical strength for the friction material, and also forms a third body layer under higher temperature conditions.

Whiskers--The White is New Gold

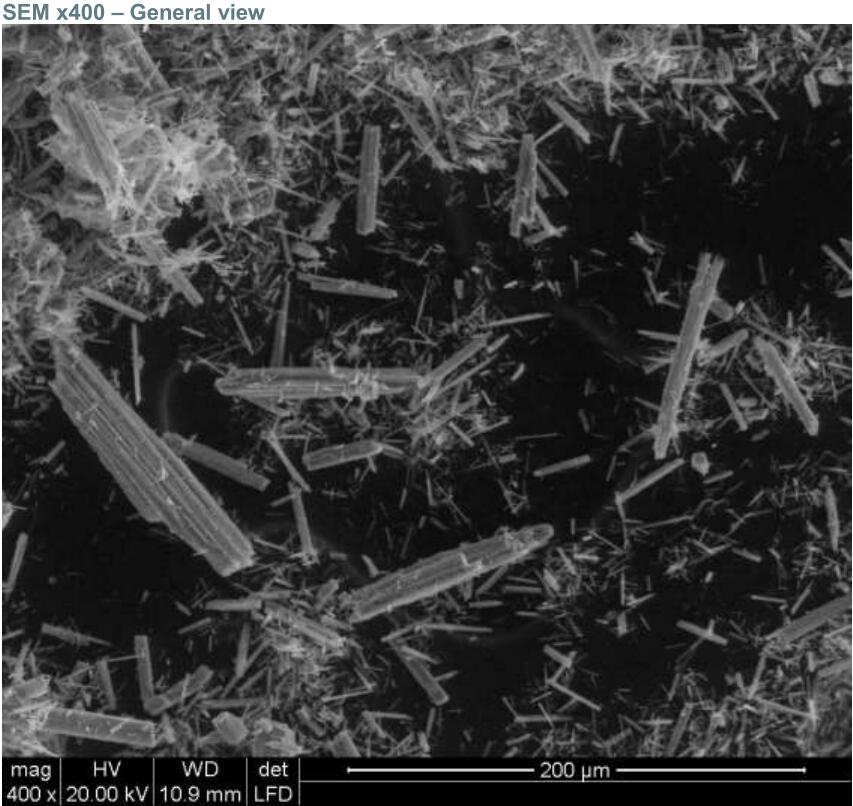

Whisker generally refers to a fiber grown in the form of a single crystal under artificially controlled conditions (main form), its diameter is very small (in micron level), and does not contain defects (such as grain boundaries, dislocations, holes) existing in ordinary materials, its atomic arrangement is highly ordered, so its intensity is close to the theoretical value of a complete crystal. Its mechanical strength is equal to the Interatomic Force between adjacent atoms. The highly oriented structure of whiskers not only makes it have high strength, high modulus and high elongation, but also has electrical, optical, magnetic, dielectric, conductive, superconductive properties. The strength of whiskers is much higher than that of other short-cut fibers. It is mainly used as a reinforcement of composite materials and used to manufacture high-strength composite materials.

Whisker materials are mainly divided into two categories: organic whiskers and inorganic whiskers.

Inorganic whiskers mainly include non-metallic whiskers and metallic whiskers. Among them, non-metallic whiskers are mostly used in polymer materials. The strength and heat resistance of ceramic-based whiskers in non-metallic whiskers are better than those of metal whiskers, and they are a more important type of inorganic whiskers. It mainly includes carbonized silicon whiskers, silicon nitride whiskers, mullite whiskers, potassium titanate whiskers, aluminum borate whiskers, zinc oxide whiskers, magnesium oxide whiskers, calcium sulfate whiskers, calcium carbonate whiskers And magnesium salt whiskers.

Calcium Sulfate Whiskers

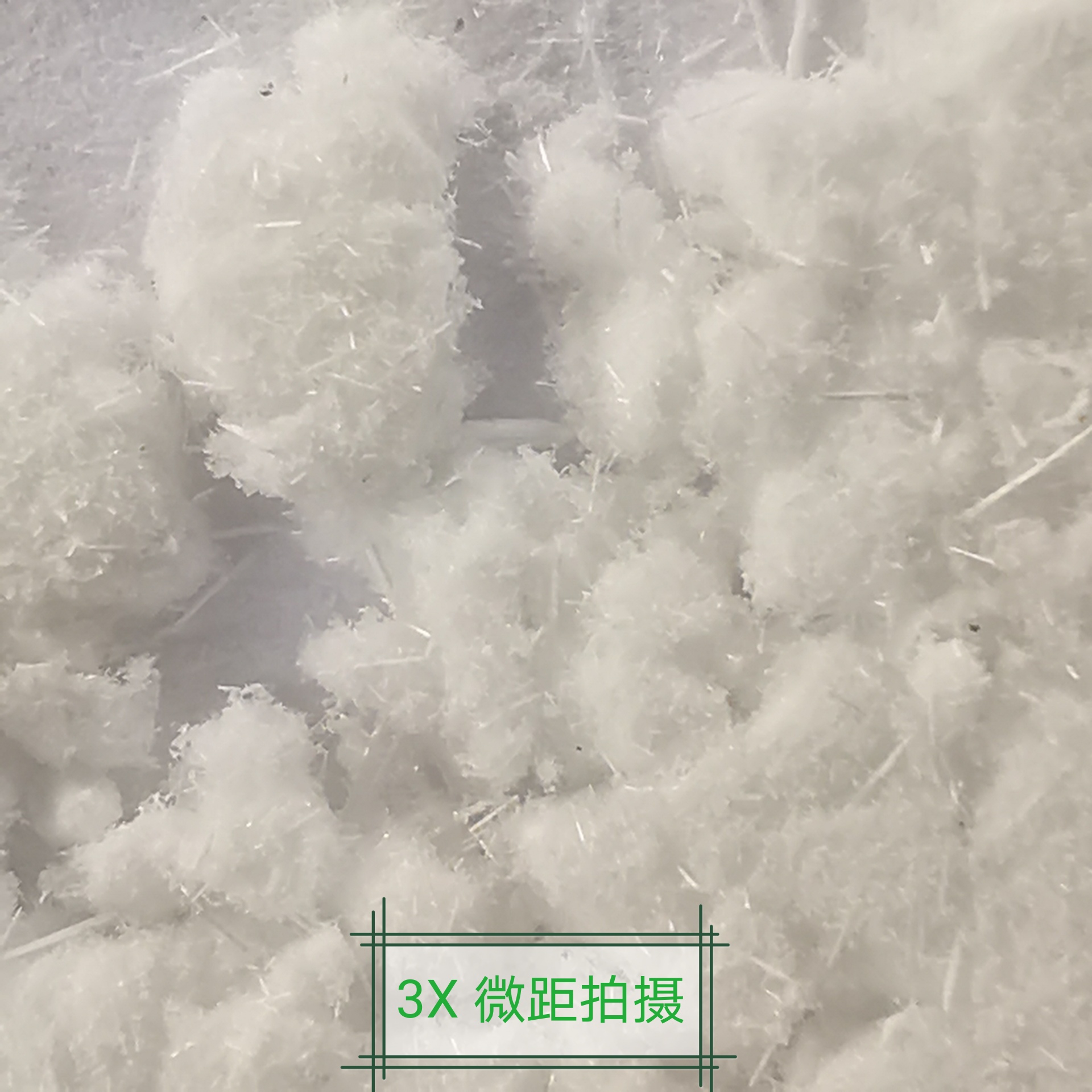

Calcium sulfate whisker is a fibrous single crystal, synthesized by raw gypsum as a raw material, through a specific process. It is a new needle-shaped fibrous sub-nanometer material with a uniform cross section, a complete shape and a perfect internal structure grown in the form of a single crystal. It has a uniform cross-section, a complete shape and a highly perfect internal structure, and many other excellent physical and chemical properties, like high strength, high modulus, high toughness, high insulation, high temperature, wear, corrosion, acid and alkali resistance, good infrared reflectivity , easy surface treatment, easy to compound with polymer, and non-toxic.

Calcium sulfate whiskers combine the advantages of reinforcing fibers and ultra-fine inorganic fillers, and can be used as a reinforcing and toughening agent or functional filler in resins, plastics, rubber, paints, paper-making, asphalt, friction and sealing materials industries. And it also can be directly used as filter materials, thermal insulation materials, fire-resistant thermal insulation materials, infrared reflective materials and high-insulation materials coated wires.

Effect of Calcium Sulfate Whiskers on Friction Material

A Calcium sulfate whiskers are safe materials.

B Calcium sulfate whiskers can be regarded as an anchor point to promote the formation of the third body layer, creating a very suitable condition for stabilizing the friction coefficient, so its shape is excellent.

C. Calcium sulfate whiskers are excellent in heat resistance, because at up to 1000 degrees Celsius, it does not show thermal degradation, provides appropriate mechanical strength for the friction material, and also forms a third body layer under higher temperature conditions.

D The Mohs hardness of calcium sulfate whiskers is 2-3, which can provide the mechanical strength of a fiber material in the friction material system, but it does not produce a hard contact point, does not scratch the friction disk, and may generate less vibration and noise.

E. During the friction material mixing process, the calcium sulfate whiskers have a good affinity with the phenolic resin, and are easy to mix, disperse and capture the fine powder to keep the entire mixture fully mixed and evenly distributed.

F. Calcium sulfate whiskers are chemically neutral and protect the metal couple from corrosion;

G. Calcium sulfate whisker have low hardness and are very fluffy, its bulk density is 0.3-0.65 g/cm3, and its specific surface area is large, thus can improve the noise problem of friction materials

Experiments

The technical personnel of the brake pad factory have the necessity of improving the original formulas. Various problems such as defects and excessive cost, need to be optimized and improved. Calcium sulfate whisker does not contain defects, which existing in ordinary materials (such as grain boundaries, dislocations, holes, etc.), and its atomic arrangement is highly ordered, so its strength is close to the theoretical value of a complete crystal, which is a very good formula improving additive. The Mohs hardness of calcium sulfate whiskers is 2-3, which can provide the mechanical strength of a fiber material in the friction material system, but it does not produce a hard contact point, does not scratch the friction disk, and may generate less vibration and noise.

We can see the test results of the following experiments:

Conclusion: Also for the results of brake pad wear rate, C>A>B, formula B has the lowest wear rate, and wear rate of A is less than C. Dynamometer tests show that NHV performance is effectively improved during braking.

Conclusion: Also for the results of brake pad wear rate, C>A>B, formula B has the lowest wear rate, and wear rate of A is less than C. Dynamometer tests show that NHV performance is effectively improved during braking.

It has been verified by multiple experiments that calcium sulfate whiskers have excellent performance when used in combination with rock wool in the NAO formula of medium and high-end car discs and low-metallic (semi-metallic) disc brake pads for commercial vehicles.

Main Application:

1. Friction sealing material industry: (automotive brake pads, train brake pads, rubber gaskets and sealing plates, etc.) used as additional materials to enhance and adjust friction performance. Calcium sulfate whiskers are non-toxic and basically have no heavy metals, so they are suitable as substitutes for asbestos.

2. Abrasive mold industry: mainly used in resin grinding wheels, which can enhance the friction performance, extend the service life, and high temperature resistance.

3. Composite material modification industry: for example: engineering plastics (car bumpers, automobile instrument panels, interior ceilings, etc.), modified plastics (nylon PA, polypropylene PP, polyethylene PVC, etc.), rubber products, etc. It is applied to polymer materials, which can not only strengthen and toughen the materials, but also play the role of thickening, heat resistance, wear resistance, oil resistance and so on.

4. Environmental protection field: Since whiskers generally have a large specific surface area, they can be used as filter materials to remove harmful impurities in exhaust gas and waste water.

5. Paper industry: It can replace pulp in part or in large quantities to produce various kinds of paper, which can greatly increase paper output, reduce wood consumption, save costs and expenses, not only protect the environment, but also reduce waste water discharge in paper-making.

6. Construction industry of metal-based and ceramic-based materials: as a reinforced additive material.

7. Paints and powders: As additional materials, paints and powders with calcium sulfate whiskers have strong adhesion, temperature resistance, and good insulation (or conductivity).

8. Asphalt modified materials: calcium sulfate whiskers can be used for asphalt fillers and reinforcing agents, which have a decisive influence on raising the softening temperature of asphalt.

So calcium sulfate whiskers have very broad application prospects in many fields.

Related Materials: