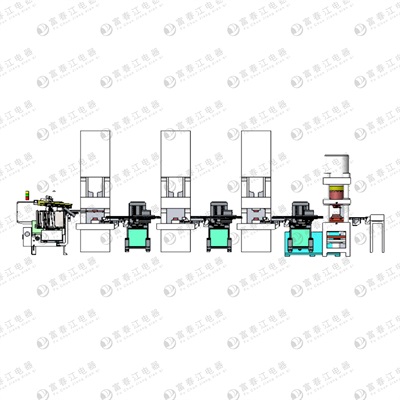

Automatic PC and CV Brake Pads Back Plates Production Machine Line

描述

PC和CV刹车片钢背生产机线是一条完整生产过程的全自动生产线,可以有效提高生产效率,降低材料成本和人工成本。

Automatic PC and CV Brake Pads Back Plates Production Machine Line is an full automatic production line for brake pads back plates with a complete production process,which can increase the prdocution capacity,reduce the material cost and labor cost.

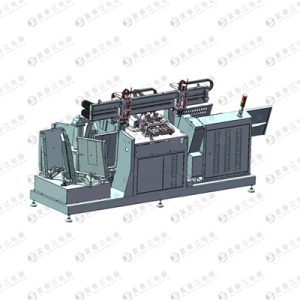

第一部分:自动钢背落料机 BL-BF606-315A

Part No.1: Automatic Backing Plates Blanking Feeder BL-BF606-315A

该机器主要旨在节省落料中板材的使用,并降低操作风险和提高生产效率。

This machine is mainly designed to reduce the material used in the steel backing plates blanking, and reduce the operation risk and improve the production efficiency.

它可以直接从板材上进行落料,具有自动切换和自动夹紧功能等。

It has the functions of direct blanking from the steel sheets, automatic line change, automatic fixture avoidance, etc.

这是一种非常有效的用于钢背冲压的辅助设备。

It is a very efficient auxiliary equipment for steel back stamping

- 单次单张板材,消除了传统的板材切割程序,减少了生产时间并提高了生产效率。

One sheet of plate at one time, eliminating the need for traditional cutting procedures, reducing production time and improving production efficiency. - 随着喂料台高度的自动调整功能(调整高度为50mm),它始终可以平行于模具的高度。

With the function of automatic adjustment of the height of the feeding table (adjustment height 50mm), it can always be parallel to the height of the mold - 交错的布局,钢板的同一区域可以产生约9%-20%的钢,从而提高了板的利用率并节省了生产成本。

Staggered layout, the same area of the steel sheet can produce about 9%-20% more steel back, which improves the utilization rate of the plate and saves the production cost.

技术参数:

Technical Parameters:

- 最大板材尺寸:3000mm*1500mm

The max. size of steel sheet: 3000mm x1500mm - 最大移动速度:500mm/s

Maximum moving speed: 500mm/s - 最大板材厚度:10mm

The max. clamping plate thickness: 10mm - 移动精度:≤±0.1mm

Movement accuracy: ≤±0.1mm - 移动平台尺寸:3000X2450mm

Working table size: 3000X2450mm - 移动平台:万向轮

Workbench form: universal ball - 夹紧方式:气动

Clamp form: pneumatic clamp - 设备功率:6.5KW

Power of the whole machine 6.5kw

第二部分:自动PC和CV 钢背的连线

Part No.2: Manipulators for CV and PC Backing Plates BL-FM808/908-HD

自动连线是完整的自动机器人臂,将靠背板从一台冲床(按压机)移至另一台冲床。 可以通过控制屏以向左和向右运行,并通过手轮来回调整。 辅助定位可以通过燕尾滑动平台进行调整。

The manipulators are full automatic robot arms, moving the backing plates from one punching machine(pressing machine) to another. The body can be adjusted through the screen to run left and right, and through the hand wheel to adjust back and forth. The secondary positioning can be adjusted by dovetail sliding platform.

最大工件尺寸: 长度260mm*宽度120mm; 最小工件尺寸: 长度60mm*宽度40mm;

Supporting work-piece size: max. L260mm*W120mm; min. L60mm*W40mm;

技术参数:

Technical Parameters:

- Punch Machine: 1100KN/1250KN/1600KN

- Main Robot Machine: Feeding Materials

- Punch Machine: Holes Punch

- Punch Machine: Pins Punch

- Punch Machine: Side Punch

- Hydraulic Press Machine:3250KN; Fine Blanking

- Robot Hands: Moving/Reversal

- Deburring Machine:Removing Burrs On Back Plates

- 冲床:1100KN/1250KN/1600KN

- 主机器人:喂料

- 冲床 1:冲孔

- 冲床 2:拔钉

- 冲床 3:压边

- 液压机:3250KN; 精修+整平

- 机器人手臂:移动/翻转

- 去毛刺机:去除钢背毛刺。

Automatic PC and CV Brake Pads Back Plates Production Machine Line

第二部分-A:连线存储和喂料机构

Part No.2-A: The Blanked Backing Plates Holder and Feeders BL-BM808-HD

落料钢背存储及喂料机构配有全自动机器手,它可以存储5行钢背(500片每次)。 它是带有自动机器人臂将背板从支架移动到第一台冲床。可以通过屏幕调节身体以向左和向右运行,并通过手轮来回调整。 辅助定位可以通过燕尾滑动平台进行调整。

The blanked backing plates holder and feeders are full automatic robot arms, it can stock five rows of blanked backing plates(500 pcs each time). It is with an automatic robot arm moving the backing plates from the holder to the first punching machine.. The body can be adjusted through the screen to run left and right, and through the hand wheel to adjust back and forth. The secondary positioning can be adjusted by dovetail sliding platform.

最大工件尺寸: 长度260mm*宽度120mm;最小工件尺寸:长度60mm*宽度40mm

Supporting work-piece size: max. L260mm*W120mm; min. L60mm*W40mm;

第二部分-B:C型固定式钢背冲床设备

Part No.2-B: Automatic C-Frame Fixed Bolster Punch Machine

C型系列固定式冲床是最适合乘用车刹车片钢背生产的类型,该型冲床配有湿离合器,液压保护泵,自动/手动润滑系统,滑块和上部模具,触摸屏的平衡系统, 电子曲轴角指示器,凸轮控制器和PLC。

The C-Frame Series Fixed Bolster Punch Machine is the most suitable type for blanking passenger car backing plates, which is equipped with Wet Clutch, hydraulic overland protecting pump, Auto/Manual lubrication system, balance system for slider and upper die, touch screen, electronic crankshaft angle indicator, cam Controller and PLC.

- 传输形式:曲轴连接杆结构,曲轴纵向排列,支点距离短,结构是紧凑的。

Main transmission form: crankshaft connecting rod structure, the crankshaft is arranged longitudinally with a short fulcrum distance, and the structure is compact. - 驱动模式:高扭矩湿离合器。 高扭矩的湿离合器具有低惯性,高扭矩,无污染和低噪声的特征。 它符合环境保护要求,寿命长,维护成本较低。

Drive mode: high torque wet clutch. The high-torque wet clutch has the characteristics of low inertia, high torque, no pollution, and low noise. It meets environmental protection requirements, has a long life and low maintenance costs. - 滑块采用了延长的六面导轨,润滑导轨板由复合材料制成,该材料具有很高的指导精度和良好的耐磨性。 滑块配备了液压超载保护设备,当超过额定吨位的10%时,该设备会生成过载卸载警报。 滑块会自动停止。 超载后,需要将其移回顶部的死亡中心一英寸,液压超载装置会自动补偿压力。

The slider adopts an extended six-sided guide rail, and the lubricating guide rail plate is made of composite material, which has high guiding accuracy and good wear resistance. The slider is equipped with a hydraulic overload protection device, which generates an overload unloading alarm when about 10% of the rated tonnage is exceeded. The slider automatically stops. After an overload, it needs to be moved back to the top dead center by an inch, and the hydraulic overload device automatically compensates for pressure. - 所有加工都均在PAMA和铣削加工中心完成,一次性夹紧,以确保机床的形状和位置的准确性。

All body processing is completed on the PAMA boring and milling machining center, one-time clamping to ensure the accuracy of the machine tool’s shape and position. - 机身采用由钢板焊接的箱体结构,采用二氧化碳气体屏蔽焊接,并经历调速以减轻压力。 它具有高强度和刚性,并且几何精度和稳定性高。

The machine body adopts a box-shaped structure welded by steel plates, adopts CO2 gas shielded welding, and undergoes tempering to relieve stress. It has high strength and rigidity, and high geometric accuracy and stability. - Main operation panel: color touch screen, main motor running indicator.

主操作面板:彩色触摸屏,主电机运行指示器。

技术参数:

Technical Parameters:

- BL-WCP21-125T

- Nominal Force: 1250KN

- Motor Power: 11KW

- Nominal Stroke: 6mm

- Slide Stroke: 180mm

- Slide Strokes/minute: Fixed is 50; Variable is 35-60

- Die Setting Height: 350mm

- Die Height Adjustment: 90mm

- Throat Depth: 350mm

- Distance Between Uprights: 670mm

- Slide Bottom Size: LxR is 620mm; FxB is 520mm

- Shank Hole Size: φ70mm; Depth 80mm

- Bolster Size: LxR is 1100mm; FxB is 680mm

- Blanking Hole Diameter: φ200mm

- Bolster Thickness: 155mm

- Bolster Surface Height: 900mm

- Overall Dimensions(LxWxH): 2040x1320x3035mmBL-WCP21-125T

- 公称力:1250KN

- 电机功率:11kW

- 公称力行程:6mm

- 滑块行程:180mm

- 滑动/分钟:固定为50; 变量为35-60

- 模具设置高度:350mm

- 高度调整:90mm

- 滑块中心到机身距离:350mm

- 立柱之间的距离:670mm

- 滑块底部尺寸:左右为620mm; 前后为520mm

- 模柄孔尺寸:φ70mm; 深度80mm

- 工作台板尺寸:左右为1100mm; 前后为680mm

- 落料孔直径:φ200mm

- 工作台板厚度:155mm

- 工作台表面高度:900mm

- 总体尺寸(LXWXH):2040x1320x3035mm

- BL-WCP21-160T

- Nominal Force: 1600KN

- Motor Power: 15KW

- Nominal Stroke: 6mm

- Slide Stroke: 200mm

- Slide Strokes/minute: Fixed is 45; Variable is 30-55

- Die Setting Height: 400mm

- Die Height Adjustment: 100mm

- Throat Depth: 400mm

- Distance Between Uprights: 736mm

- Slide Bottom Size: LxR is 700mm; FxB is 580mm

- Shank Hole Size: φ70mm; Depth 100mm

- Bolster Size: LxR is 1175mm; FxB is 760mm

- Blanking Hole Diameter: φ220mm

- Bolster Thickness: 165mm

- Bolster Surface Height: 900mm

- Overall Dimensions(LxWxH): 2305x1420x3215mm

- 公称力:1600KN

- 电机功率:15kW

- 公称力行程:6mm

- 滑块行程:200mm

- 滑动/分钟:固定为45; 变量为30-55

- 模具设置高度:400mm

- 高度调整:100mm

- 滑块中心到机身距离:400mm

- 立柱之间的距离:736mm

- 滑块底部尺寸:左右为700mm; 前后为580mm

- 模柄孔尺寸:φ70mm; 深度100mm

- 工作台板尺寸:左右为1175mm; 前后为760mm

- 落料孔直径:φ220mm

- 工作台板厚度:165mm

- 工作台表面高度:900mm

- 总体尺寸(LXWXH):2305x1420x3215mm

- BL-WCP21-200T

- Nominal Force: 2000KN

- Motor Power: 18.5KW

- Nominal Stroke: 6mm

- Slide Stroke: 200mm

- Slide Strokes/minute: Fixed is 45; Variable is 30-55

- Die Setting Height: 450mm

- Die Height Adjustment: 110mm

- Throat Depth: 430mm

- Distance Between Uprights: 910mm

- Slide Bottom Size: LxR is 880mm; FxB is 650mm

- Shank Hole Size: φ70mm; Depth 100mm

- Bolster Size: LxR is 1390mm; FxB is 840mm

- Blanking Hole Diameter: φ240mm

- Bolster Thickness: 180mm

- Bolster Surface Height: 1000mm

- Overall Dimensions(LxWxH): 2600x1540x3800mm

- 公称力:2000KN

- 电机功率:18.5kW

- 公称力行程:6mm

- 滑块行程:200mm

- 滑动/分钟:固定为45; 变量为30-55

- 模具设置高度:450mm

- 高度调整:110mm

- 滑块中心到机身距离:430mm

- 立柱之间的距离:910mm

- 滑块底部尺寸:左右为880mm; 前后为650mm

- 模柄孔尺寸:φ70mm; 深度100mm

- 工作台板尺寸:左右为1390mm; 前后为840mm

- 落料孔直径:φ240mm

- 工作台板厚度:180mm

- 工作台表面高度:1000mm

- 总体尺寸(LXWXH):2600x1540x3800mm

- BL-WCP21-400T

- Nominal Force: 4000KN

- Motor Power: 37KW

- Nominal Stroke:8mm

- Slide Stroke: 250mm

- Slide Strokes/minute: Fixed is 30; Variable is 20-35

- Die Setting Height: 550mm

- Die Height Adjustment: 120mm

- Throat Depth: 490mm

- Distance Between Uprights: 1050mm

- Slide Bottom Size: LxR is 1020mm; FxB is 750mm

- Shank Hole Size: φ70mm; Depth 140mm

- Bolster Size: LxR is 1700mm; FxB is 950mm

- Blanking Hole Diameter: φ240mm

- Bolster Thickness: 210mm

- Bolster Surface Height: 1100mm

- Overall Dimensions(LxWxH): 2850x1750x4140mm

- 公称力:4000KN

- 电机功率:37kW

- 公称力行程:8mm

- 滑块行程:250mm

- 滑动/分钟:固定为30; 变量为20-35

- 模具设置高度:550mm

- 高度调整:120mm

- 滑块中心到机身距离:490mm

- 立柱之间的距离:1050mm

- 滑块底部尺寸:左右为1020mm; 前后为750mm

- 模柄孔尺寸:φ70mm; 深度140mm

- 工作台板尺寸:左右为1700mm; 前后为950mm

- 落料孔直径:φ240mm

- 工作台板厚度:210mm

- 工作台表面高度:1100mm

- 总体尺寸(LXWXH):2850x1750x4140mm

第二部分-C:整平机

Part No.2-C: Leveling Press Machine

在之前的生产过程中,钢背平整度将受到影响,需要使用整平机来保证钢背的平整度。

During the previous procedures, the backing plates flatness will be affected. Leveling Press Machine is used to calibrate the flatness of the steel back, after fine pressing.

技术参数:

Technical Parameters:

- BL-325T-HP

- Nominal Capacity of Ram Cylinder: 2000KN

- Nominal Capacity of Cushion Cylinder: 1250KN

- Max Working Pressure:25MPA

- Open Height: 500mm

- MaStroke of Ram Cylinder: 300mm

- MaStroke of Cushion Cylinder: 300mm

- Cylinder Speed: 20 rpm

Ram Cylinder Down: 300mm

Ram Cylinder Up: 260mm

Cushion Cylinder Up: 100mm

Cushion Cylinder Pressing: 12mm - Motor Power: 15KW

- Bolster Surface Height: 900mm

- Bolster Surface Size: LxR is 600mm; FxB is 650mm

- Oil Pump Discharge Capacity: 63 ml/r

- 上缸公称力:2000KN

- 下缸公称力:1250KN

- 最大工作压力:25MPA

- 最大开口高度:500mm

- 上缸行程:300mm

- 下缸行程:300mm

- 气缸速度:没分钟完成20次循环

- 上缸快下:300mm

- 上缸回程:260mm

- 下缸快上:100mm

- 下缸回程:12mm

- 电机功率:15kW

- 工作台面高度:900mm

- 台面尺寸:左右为600mm; 前后为650mm

- 油泵排量:63 mL/r

- BL-515T-HP

- Nominal Capacityof Ram Cylinder: 3150KN

- Nominal Capacityof Cushion Cylinder: 2000KN

- Ma Working Pressure:25MPA

- Open Height: 500mm

- MaStroke of Ram Cylinder: 300mm

- MaStroke of Cushion Cylinder: 300mm

- Cylinder Speed: 20 rpm

Ram Cylinder Down: 300mm

Ram Cylinder Up: 260mm

Cushion Cylinder Up: 100mm

Cushion Cylinder Pressing: 12mm - Motor Power: 18.5KW

- Bolster Surface Height: 900mm

- Bolster Surface Size: LxR is 600mm; FxB is 650mm

- Oil Pump Discharge Capacity: 80 ml/r

- 上缸公称力:3150KN

- 下缸公称力:2000KN

- 最大工作压力:25MPA

- 最大开口高度:500mm

- 上缸行程:300mm

- 下缸行程:300mm

- 气缸速度:没分钟完成20次循环

- 上缸快下:300mm

- 上缸回程:260mm

- 下缸快上:100mm

- 下缸回程:12mm

- 电机功率:18.5kW

- 工作台面高度:900mm

- 台面尺寸:左右为600mm; 前后为650mm

- 油泵排量:80 mL/r