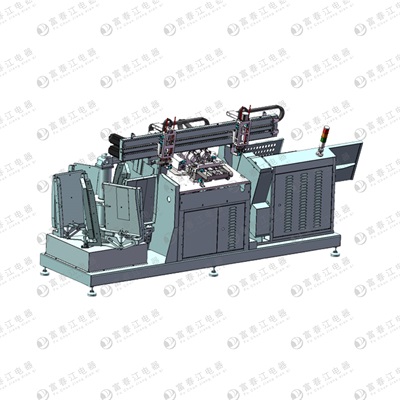

Brake Pads Back Plates Automatic Holes Drilling Machine

描述

刹车片钢背智能钻孔机总体方案及主要机构描述

Brake Pads Back Plates Automatic Holes Drilling Machine is used to drill the holes on top of brake pad back plates, with fullly automatic feeding, drilling, and stocking process.

设备描述:

Machine Description:

- 具备储料、钻孔、收料一体化特性。

- 储料仓容量大,方便材料的存储。

- 通过机械手将产品放至定位平台。

- 可根据角度、深度、位置等要求对钻孔智能化钻孔。

- 正常运转下,运营速率可达约每分钟7-10片产品钻孔。

- 收料仓容量大,可方便堆叠更多钢背。

- 数字化控制面板,可以方便直观的进行操作。

- 料仓具有感应区,满料会进行报警,防止产品推出料仓。

- It combines material storage, drilling and material collection into one machine.

- The storage bin has a large capacity and is convenient for material storage.

- The backing plate is placed on the positioning platform through the robot.

- Intelligently drilled according to angle, depth, position and other requirements.

- Under normal operation, can reach about 7-10 pcs per minute

- The collection bin has a large capacity, can easily stack large quantity backing plates.

- Digital control panel allows convenient and intuitive operation.

- The collection bin has a sensing area. When it is full, an alarm will be issued to prevent backing plates from being pushed out.

设备优势:

Machine’s Advantage:

- 它能代替部分人工操作完成产品的传送和加工;

- It can replace some manual operations to complete the transmission and processing of products;

- 一位员工能同时操作多台机械,提高了劳动生产率;

- One employee can operate multiple machines at the same time, which improves labor productivity;

- 减少了人为影响,使产品有良好的一致性。

- Reduce human influence and make the product have good consistency.

- 使管理简单化,减少了对专业人员的需求,能缓解工厂“用工荒”问题。

- Simplify management, reduce the need for professionals, and alleviate the problem of “labor shortage” in factories.

图一,整体布局规划图

Figure 1: Overall layout for the Brake Pads Back Plates Automatic Holes Drilling Machine